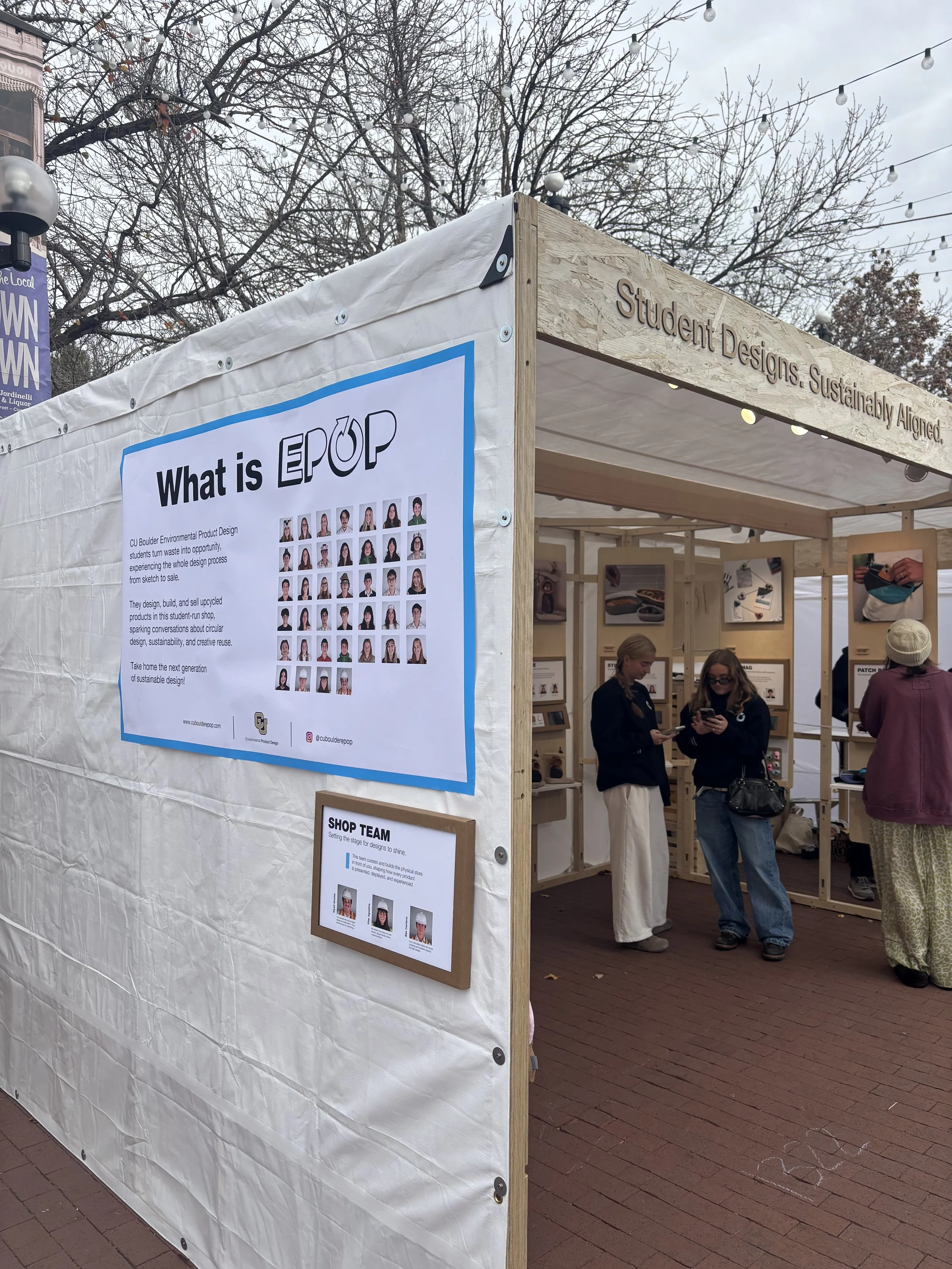

SHOP TEAM

What is EPOP?

EPOP is a course where students apply design theory to real-world projects.

In teams of three, students develop a product from sketch to scale, culminating in its sale at the Pearl Street Firefly market.

This experiential learning fosters a sense of entrepreneurship and inspires sustainable design practices.

We were tasked with updating and improving several areas of the shop.

A recently added ten-foot extension required the most attention, so it became our primary focus as a team.

Meet the EPOP Shop Team

Ben Centeno

Product Storage

Customer Experience

Branding

Pilar Agostine

Wyatt Moeller

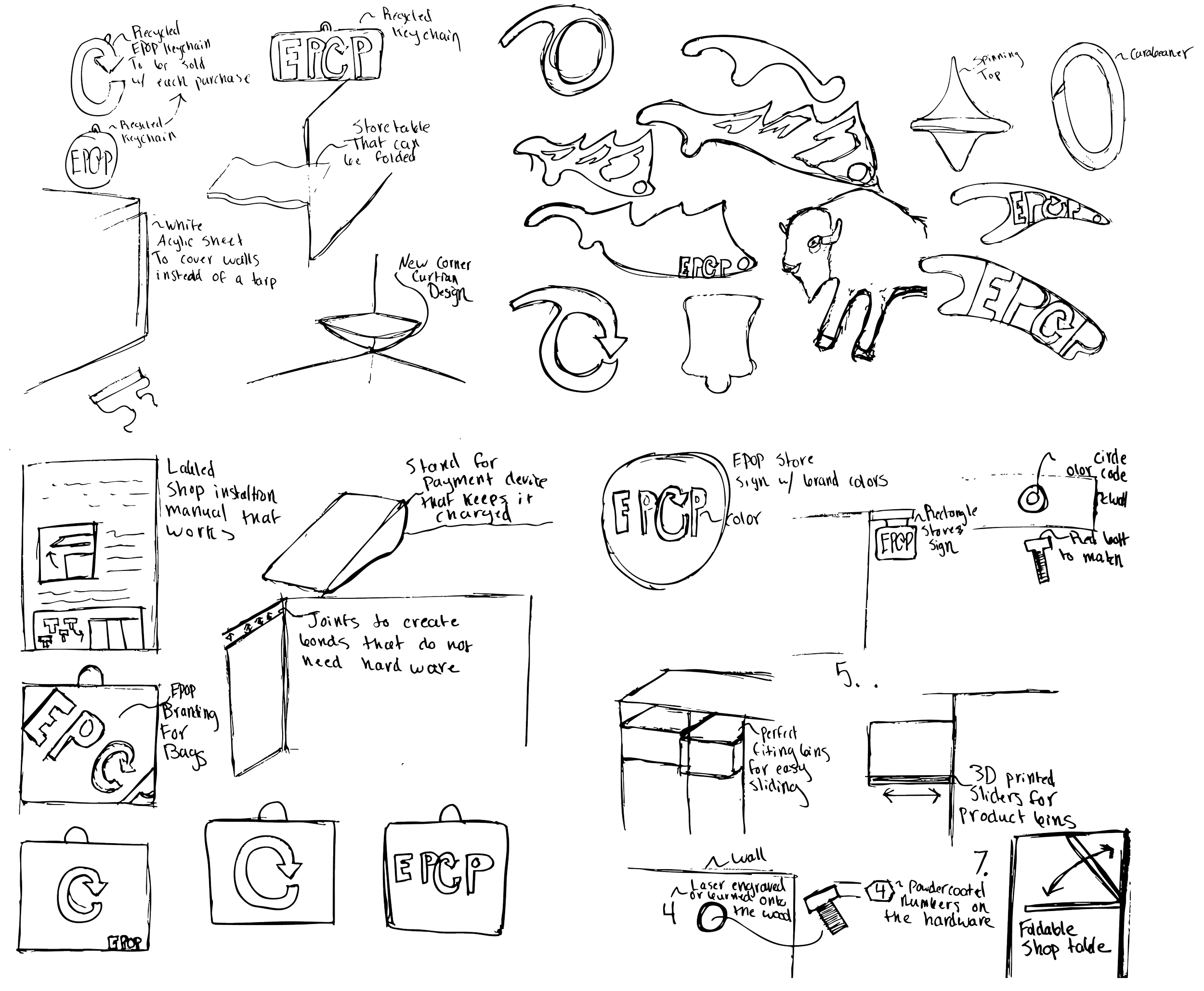

Ideation Sketches

As a member of the shop team, I was responsible for identifying an area of the space that needed improvement and developing a solution. This process involved early brainstorming and ideation sketching to explore potential directions.

Existing Shelves

After sketching, I realized the existing shelves needed significant improvement.

They lacked side and rear supports, so the bins had no guidance during use.

The column spacing was incorrect, leaving some sections too large to properly support the bins.

The top panel was also mis-sized, creating a noticeable gap at the back.

Existing Shelf Problems

Shelf Redesign

I added side guides to improve sliding, though they were not tall enough to effectively align the bins.

I introduced a backstop that worked initially, but it did not allow for bin overhang and lacked adequate structural integrity.

I widened the bottom support panel to prevent bins from slipping out of their slots, addressing a key issue in the previous design.

I added two large side-guide pieces to ensure smooth and accurate bin alignment.

In the first 3D model, I kept the original frame and redesigned only the internal insert to reduce material use.

However, the spacing was miscalculated resulting in improper bin fit.

I redesigned the second 3D model by retaining the original frame and replacing only the internal insert to reduce material use.

This time, I calculated accurate column spacing based on storage-bin dimensions.

I installed two rear stop blocks to prevent bins from sliding out the back while allowing controlled overhang and creating a sturdier, more reliable connection.

Lastly, I finalized dimensions for the shelf top and sourced a reclaimed white-laminate plywood desktop as the material.

Animation of the New Shelf Design

Before construction, I 3D-modeled and rendered the entire 10-ft store addition with each new element to ensure the pieces worked together both aesthetically and functionally.

Shelf Construction

Measured and cut all components for the shelf redesign using recycled plywood.

Assembled the insert with screws and glue, then installed it into the existing frame.

Determined the correct bin hang and added rear stop pieces for proper alignment and containment.